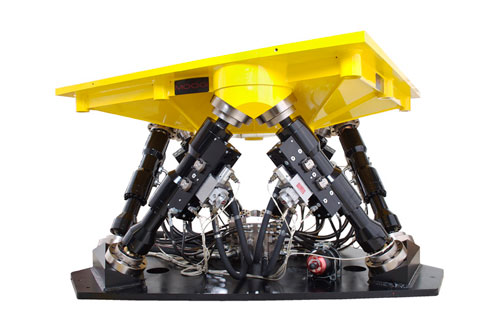

East Aurora, New York, USA ®C Moog has designed and manufactured a Hydraulic Simulation Table based on the company°Øs latest line of Hydraulic Test Actuators. This offers more capability than a conventional orthogonal system, which is a table moved by actuators mounted on its base and sides. The Moog Hydraulic Simulation Table is a six-legged hexapod with two equilateral triangular frames set one above the other, offset at 30 degrees. Each apex of the top triangle is connected to the two apexes below it via Moog Hydraulic Test Actuators with Hydrostatic Bearings.

The Moog Hydraulic Simulation Table gives users a frequency of response up to 100 Hz and can handle payloads up to 680 kg (1,500 lbs). Auto makers and independent test houses can use this latest simulation table to replicate real-world road conditions that strain automobile components, such as axles, engines, interior and exterior assemblies, seats, steering column assemblies, cooling module systems, truck and tractor cabs, and After Treatment Systems (ATS) for heavy-duty diesel applications.

Picture 1: Moog Hydraulic Simulation Table offers vector-based motion and an expanded frequency range up to 100 Hz to increase testing speed and flexibility

Picture 2: A technician testing vehicle components using the Moog Hydraulic Simulation table

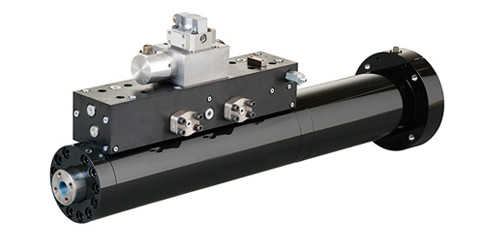

Picture 3: Specially designed hydraulic actuator for Test applications give higher level of dynamic performance, reliability and longevity

Picture 4: The full family of Moog Automotive Test Controllers incorporates unique control loop technology to test faster